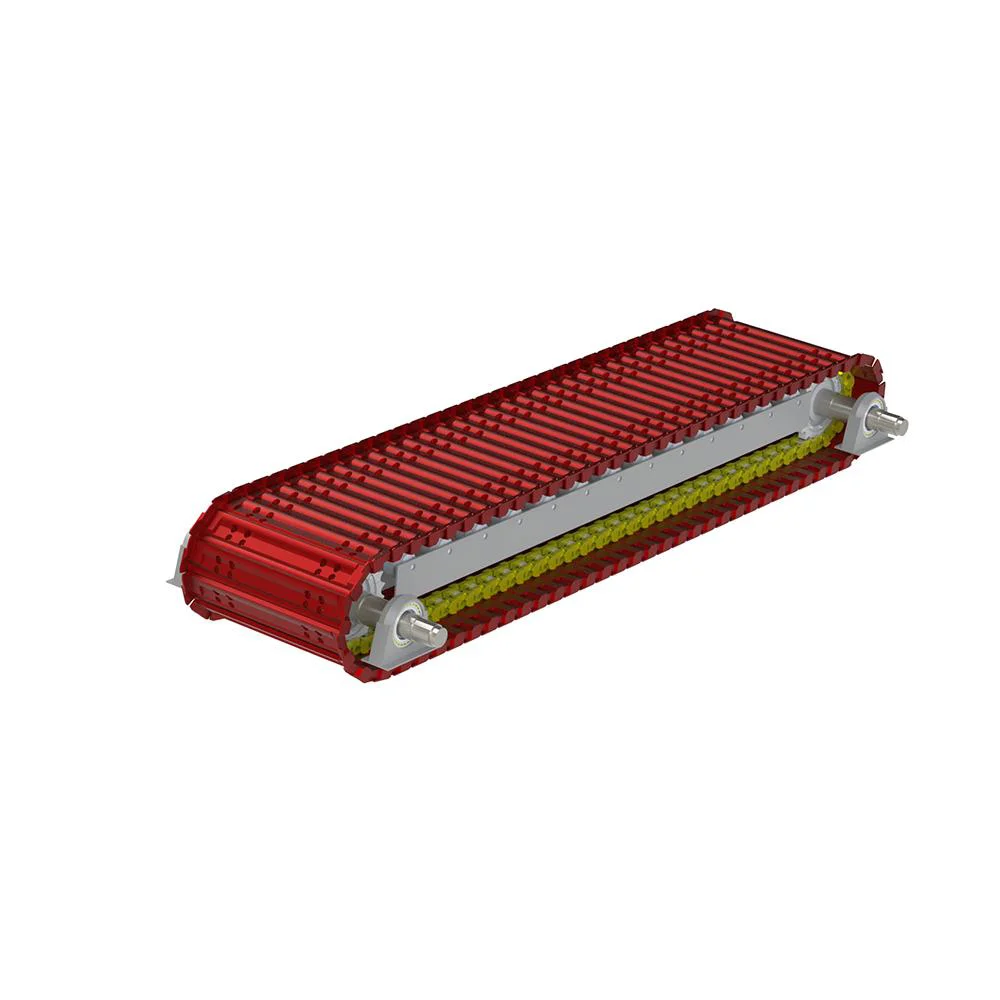

APRON FEEDER PANS

GANGWEI Apron Feeder Pans are cast for exact fit and outstanding wear life making them a top choice for mining facilities around the world.

ONE-PIECE PRECISION CASTING

Cast using the V-Process molding technique creating accurate dimensions and a good surface finish. The one-piece casting method eliminates failure due to weld cracks—a common problem with traditional fabrication—ensuring greater durability and wear life.

WORK HARDENING ALLOY

Heavy-duty cast Austenitic Manganese Steel (M2) for high impact resistance. Save in replacement costs and downtime with apron feeder pans that get stronger the harder you work them! Cast using a heavy duty alloy that work hardens under high-load conditions and impact for maximum wear life and reduced maintenance.

EXACT FIT

The bolting surfaces are machined to ensure 100% contact when assembled to the drive chains.

RECESSED-HEAD BOLT HOLES

Recessed-head bolt holes protect bolt heads for longer wear life.

HEAT-TREATED

Heat-treated for Maximum Ductility

TESTED BEFORE DELIVERY

Test-assembled at the factory to identify any fit problems long before material is installed on site.

FEATURES & BENEFITS

- Cast not to crack! No welds eliminates risk of failure at joins.

- Cast in work-hardening manganese steel (M2) – gets stronger the more it’s used.

- Performance features such as heat treating, and recessed bolt holes extended wear life even further.

- Tapered design to reduce product build up.

- Interchangeable with other proprietary pans for convenience.